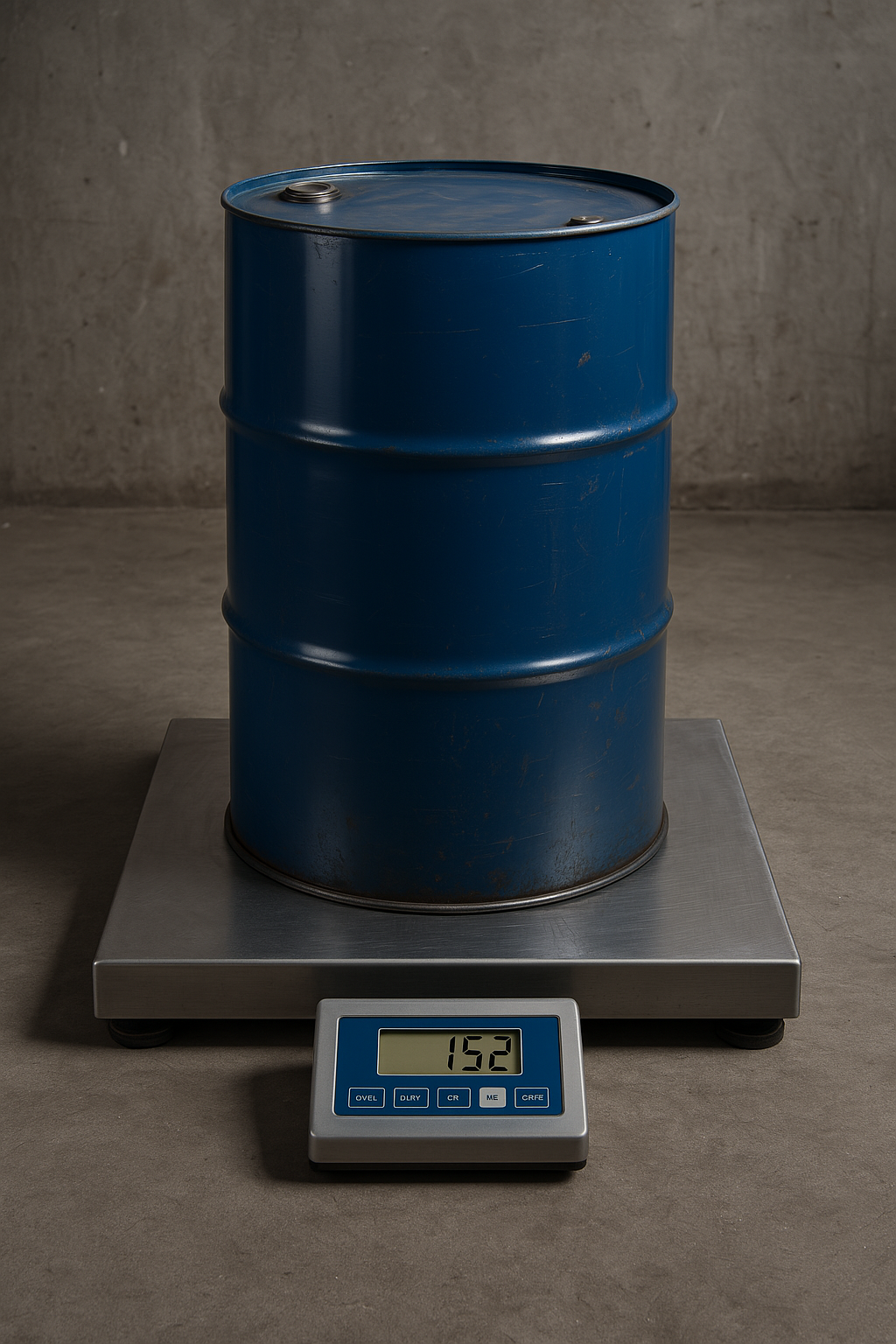

Cylinder And Drum Scales

Enhance safety, compliance, and precision with LSI’s cylinder and drum scales, engineered for ±0.1% accuracy and certified to meet ATEX, OSHA, and ISO standards. Ideal for chemical, pharma, logistics, and gas-handling industries, our systems reduce measurement errors by up to 92% and integrate seamlessly with your ERP. Custom-built for harsh environments, corrosive materials, and non-standard drum sizes.

Request A Callback

Cylinder & Drum Scales: Industrial-Grade Weight Measurement

How much risk are you taking by relying on guesswork when weighing hazardous or high-value materials? In environments where every gram matters—from chemical drums to medical gas cylinders—accuracy isn’t optional. LSI Scales delivers engineered cylinder and drum scales designed for precision weighing in high-demand sectors like pharma, logistics, and chemical manufacturing.

Our solutions are built to meet OSHA compliance and hazardous material handling standards, backed by a ±0.1% accuracy guarantee and more than 50 industry-recognized certifications, including ISO 13485, ATEX, and NIST. These are not just scales—they’re safeguards for your processes, your people, and your profitability.

If you’re in search of industrial weighing solutions that meet rigorous specifications and scale with your needs, call (559) 446-1022 today or read on to uncover the signs it’s time for a serious upgrade.

(559)446-1022

Give us a call:

(855) 440-1022

Give us a call:

When to Upgrade to Industrial Drum Weighing Systems

Is your team still relying on estimates when it comes to critical drum weight measurement? Inaccurate readings can lead to overfills, OSHA violations, or even dangerous overloads—all of which can quietly erode your operational safety and bottom line. LSI Scales helps facilities transition to cylinder weighing systems that eliminate error-prone processes and bring your inventory under control.

- Frequent Overload Incidents

If your storage or transport systems are showing signs of strain, inaccurate fills may be to blame. - Inventory Doesn’t Match Output

Manual weighing leads to inconsistencies that create reporting headaches and lost product. - Rising Compliance Costs

Heavy-capacity weighing errors can lead to fines or recalls that could have been avoided.

Reduce measurement errors by up to 92%—call (559) 446-1022 or keep reading to see why 1,000+ facilities choose LSI drum scales.

Fully-Insured & Certified Expertise

Comprehensive Weighing Solutions

Strategic Location Advantage

Cost-Effective & Eco-Friendly

24/7 365 Days a Year

Fastest Response Time

All Work Fully Guaranteed

Over 50 years of reliability

Engineered for Safety: Explosion-Proof Drum Scales

When safety and compliance are non-negotiable, facilities turn to weighing systems they can trust. That’s why over 1,000 industrial operations rely on LSI Scales for dependable, ATEX-certified industrial weighing solutions built to withstand harsh, hazardous conditions. Our durable industrial scales are engineered with stainless steel load cells, sealed to IP67 standards, and designed for environments where flammable vapors, corrosive materials, or volatile gases are present.

- Explosion-Proof Design

ATEX-compliant enclosures and intrinsically safe wiring guard against ignition in high-risk areas. - Custom Capacities for Any Application

From medical gas cylinder scales to high-capacity tank weighing, we support a range from 50 to 20,000 lbs. - Long-Term Reliability

Every system is backed by a 10-year durability warranty, ensuring consistent performance under pressure.

Want a weighing solution that meets real-world industrial demands? Call (559) 446-1022 or read on to see how we deliver ±0.1% precision, every time.

Trust Our Tried and Tested Process

Contact Us 24/7, 365

Available Every Day, All Day, to assist with weighing solutions and provide prompt, lasting results.

Fast Response

In the event of a weighing emergency, our team is ready to respond promptly and initiate immediate solutions.

Fully Equipped

We utilise the latest tools and equipment to deliver professional weighing solutions to all clients.

Thoroughly Trained

Our team is made up of highly skilled and experienced experts, all of whom provide excellent service.

Precision Drum Weighing: Load Cell Technology Explained

What gives drum scales their edge in accuracy—especially when handling volatile materials or high-capacity cylinders? At LSI Scales, it starts with advanced load cell scales engineered to deliver real-time, traceable data under dynamic weight conditions. Each system is designed for precision weighing, ensuring that even subtle fluctuations in fill levels or chemical densities are captured with ±0.25% accuracy.

- NIST-Traceable Calibration

Every drum scale is verified through certified calibration protocols to meet regulatory and production standards. - Overload Protection Architecture

Built-in safeguards prevent system drift or damage from overfilled containers. - IoT-Enabled Monitoring

Real-time cylinder weight tracking is delivered through cloud-based dashboards for live audit trails and system alerts.

Looking for dependable weight tracking with cloud access and compliance built in? Call (559) 446-1022 or read on to see the ROI LSI drum scales deliver across key industries.

How Drum Scales Reduce Waste in Pharma & Oil/Gas

Struggling with waste, compliance delays, or inconsistent batch yields? LSI’s industrial weighing solutions are trusted across pharmaceutical labs and energy facilities for a reason—they’re engineered to control variables that directly impact productivity. Our chemical industry scales are tailored to support closed-loop filling, safe drum transfer, and precise batch processing without the guesswork.

- Faster Compliance Audits

In pharmaceutical environments, our drum scales help reduce FDA audit times by up to 30% through automated, traceable records. - Minimized Material Loss

Oil and gas operations report up to 18% fewer spillage incidents after switching to sealed, overfill-resistant weighing platforms. - Streamlined Logistics Handling

Built-in safeguards improve inventory turnover and reduce packaging waste during palletized drum handling.

If your process depends on consistency, it’s time to optimize. Call (559) 446-1022 for your site-ready quote—or read on to see how our systems scale across industries.

Available 24/7, 365 Days a Year

Our work is guaranteed

Contact our fast response team

Absolutely no hidden fees

Best Drum Scales for Medical, Logistics & 6 Key Sectors

Not every industry can rely on off-the-shelf solutions—especially when safety, sanitation, or space constraints are non-negotiable. That’s why LSI’s durable industrial scales are engineered for specialized use across sectors where precision and certification matter most. From ISO 13485-compliant medical environments to high-volume logistics hubs, our systems are built for real-world conditions.

- Medical & Pharmaceutical: Designed for cleanroom compatibility, our gas cylinder scales support safe handling of volatile or pressure-regulated compounds.

- Warehousing & Logistics: Streamline workflows with palletized drum platforms that reduce bottlenecks and increase throughput.

- Hazardous Zones: Available explosion-proof scales meet ATEX standards for chemical and oil/gas facilities.

Whether you’re tracking sterilized gas cylinders or bulk materials in transit, we’ve got a solution that fits. Call (559) 446-1022 or continue below to explore how we simplify installation and integration

Seamless Drum Scale Setup: Site Prep to Cloud Integration

Worried that installing new weighing systems will stall your workflow? LSI’s cylinder and drum scales are designed for quick deployment and long-term integration—without disrupting your operations. Our process begins with a tailored site evaluation and ends with a fully networked, ERP-ready scale that delivers real-time data where you need it most.

- Site Preparation & Inspection: Every installation starts with a foundation analysis to ensure proper anchoring, weight distribution, and safety compliance.

- Factory Calibration: Each system arrives NIST-traceable and pre-calibrated for immediate use, eliminating on-site guesswork.

- System Integration: Scales are fully compatible with ERP platforms and cloud dashboards for inventory, compliance, and live tracking.

Looking to fast-track your upgrade? Our team handles the full setup in under 48 hours. Call (559) 446-1022 to schedule your free site survey—or keep reading to explore customization options

Your Expertise Matters: Read Reviews & Share Your Insights

EXCELLENTTrustindex verifies that the original source of the review is Google. Highly recommended. Their technicians are highly skilled, efficient and professional. Outstanding scales service, installation, troubleshooting and repairing.Trustindex verifies that the original source of the review is Google. Frank and the staff at LSI scales are the best. The Rice Lake truck scales are second to none. Would recommend them to anyone needing professional sales and service at a fair price.Trustindex verifies that the original source of the review is Google. Absolutely the best customer service.Trustindex verifies that the original source of the review is Google. LSI Scales are phenomenal Superb customer service And the owners work side by side with employees Very generous, supporting the local 4H & FFA.Trustindex verifies that the original source of the review is Google. Great people, great service, fair pricesTrustindex verifies that the original source of the review is Google. I can’t say enough about what a great company LSI Scales is! They pride themselves in outstanding customer service and pay attention to every detail! The owners are the most honest and hard working people I’ve ever met!!!Trustindex verifies that the original source of the review is Google. Great work.. always on time and budgetTrustindex verifies that the original source of the review is Google. Genuine honest people!Trustindex verifies that the original source of the review is Google. Used them at a plant I managed will always be my first and last call for scales and scale work

Always On Time, Always On Budget

Transparent & Fair Pricing

We’ll break down the cost of our services and ensure that you get the best price for your situation.

Punctual, Professional, Proactive

Our team can be with you in no time to deliver expert Weighing Solutions with speed and efficiency.

Cost-Effective & Eco-Friendly

We take an environmentally conscious approach while still delivering affordable solutions to clients.

Highly Rated

Past clients have been left wholly satisfied by our efforts and have left stellar reviews of our services.

Get in Touch

Reach out to our experts today and take advantage of our reliable Weighing services. Call now at (559)446-1022 or fill out the contact form below.

Custom-Engineered Drum Scales: Capacities & Environments

Does your operation demand more than a one-size-fits-all solution? At LSI Scales, we specialize in custom-engineered cylinder and drum scales built to adapt to the unique demands of your environment—whether that means extreme heat, heavy-capacity weighing, or irregular drum sizes.

Our systems are constructed using corrosion-resistant alloys ideal for chemical exposure and can be tailored to fit non-standard footprints, varying diameters, or high-throughput workflows. Whether you’re managing bulk materials in extreme temperatures or weighing sensitive compounds in controlled rooms, we offer configurations that evolve with your operation.

From explosion-proof zones to mobile tank weighing, your process deserves flexibility without sacrificing precision. Call (559) 446-1022 to discuss a configuration built around your challenges—or read on to discover how we test for long-term durability and compliance.

How We Stress-Test Every Drum Scale (0.1% Accuracy)

How do you know your scale will hold up in a high-risk, high-output environment? At LSI Scales, we don’t just promise precision—we prove it. Every unit, including our anti-slip platform scales, goes through an extensive quality protocol rooted in ISO/IEC 17025 certification and validated by field-proven results.

- Environmental Cycle Testing

Each drum scale is run through a 72-hour load simulation, replicating the exact temperature shifts, pressure variances, and weight surges expected in your facility. - Surface Stability Validation Anti-slip platforms

are tested for traction, chemical exposure, and drum movement under load—critical for safety in fast-paced environments. - 100+ QA Checkpoints

From weld integrity to sensor calibration, every checkpoint is logged and signed off by certified technicians.

If 0.1% accuracy matters to your operation, let’s get you certified-ready. Call (559) 446-1022 or continue to learn how we maintain that performance long-te

(559)446-1022

Give us a call:

(855) 440-1022

Give us a call:

Drum Scale Uptime Guarantee: 98% Operational Reliability

What happens when your scale goes down mid-shift—or worse, mid-batch? With LSI Scales, you won’t be left waiting. We back our precision weighing systems with a 98% uptime guarantee and full access to 24/7 emergency support. From same-day spare parts to live diagnostic tools, every support plan is built to minimize disruption and protect productivity.

Our predictive maintenance programs monitor wear patterns and performance trends before failure occurs, giving your team the power to stay ahead of issues. And if something does go wrong, you’re covered with 15-minute response time commitments and remote troubleshooting included in every service tier.

Don’t risk production stoppages or non-compliance penalties—call (559) 446-1022 to speak with a support technician, or read on to explore our complete weighing ecosystem.

FAQs: Industrial Cylinder & Drum Scales

LSI’s ATEX-certified scales (50-20,000 lb capacity) feature intrinsically safe wiring, IP67-sealed load cells, and 316L stainless platforms. Compared to generic scales, our systems undergo 72-hour environmental cycle testing (-40°F to 122°F) and include NIST-traceable calibration certificates. Pharma plants using our scales report 92% fewer measurement errors and 30% faster FDA audits. Explore technical specs →

Our cloud-connected scales reduce material loss by 18% through real-time overfill alerts. Case studies show:

- $287k/year savings from avoided recalls (West Coast Pharma Co.)

- 48-hour ERP integration via Modbus/Profibus protocols

- 10-year warranty vs. industry-standard 3 years View pharma case study →

Comparison Table:

| Feature | LSI Scales | Industry Average |

| Load Cell Material | 17-4PH Stainless Steel | Aluminum Alloy |

| Calibration Interval | 24 months (NIST) | 6-12 months |

| Overload Protection | 150% rated capacity | 125% rated capacity |

Testimonial: “Zero drift after 2 years in chlorine gas storage” – ChemCo, AZ

We Engineer Solutions for:

- Oversized Drums: Up to 96″ diameter platforms

- High-Throughput: 150+ weighments/hour with RFID tagging

- Mobile Units: Forklift-compatible designs with 98% uptime SLA “LSI retrofitted our legacy system in 3 days” – Logistics Manager, Fresno Get custom quote →

Key Differentiators:

- 50+ Certifications: ISO 13485, MSHA 30 CFR §56/57, NVLAP Lab Code 200636-0

- Predictive Maintenance: IoT sensors alert technicians 72hrs pre-failure

- Local Support: 90-min response in CA/AZ with bilingual staff

- Cost Factor: No hidden fees – installation included in 10-year warranty

What our clients say

“I’ve relied on LSI Scales for years. Their quick repairs and accurate calibration are why our measurements are always on point. They’re essential to our precision scales!”

John S. - Manufacturing Manager

“LSI Scales excels in precision for our mining site. Their heavy-capacity scales and expert calibration guarantee pinpoint accuracy. They’ve been key to our operation’s success for years.”

David H. - Mining Operations Director

“LSI Scales is our go-to for peak season rentals. Their vast inventory and quick delivery have saved us countless times. We rely on LSI Scales, and they always deliver!”

Sarah M. - Logistics Coordinator

LSI Scales has been a game changer for our livestock operations in Fresno. Their quick calibration services ensure our scales are always accurate, which is crucial for our business. Highly recommend their expertise!

John D. - Fresno, CA

As a logistics coordinator in Phoenix, I rely on LSI Scales for peak season rentals. Their vast inventory and prompt delivery saved us during a critical time. They truly understand the needs of their clients!

Sarah M. - Phoenix, AZ

For our mining operations in Las Vegas, LSI Scales has provided exceptional service. Their heavy-capacity scales guarantee pinpoint accuracy. Their expert technicians are always ready to assist!

David H. - Las Vegas, NV

LSI Scales has been our trusted partner for industrial scales in Portland. Their scale installation and maintenance services are top-notch, ensuring our operations run smoothly. A reliable choice for any business!

Emily R. - Portland, OR

In Seattle, LSI Scales stands out for their commitment to precision. Their quick repair services have kept our operations efficient, and their knowledgeable staff is always a pleasure to work with!

Michael T. - Seattle, WA

Beyond Drums: Truck, Floor & Tank Scales by LSI

Looking for a single-source provider that covers more than just drums and cylinders? At LSI Scales, our industrial weighing solutions go far beyond the basics. We engineer and support a complete ecosystem—from forklift scales that boost warehouse throughput, to floor and tank scales designed for corrosive or hazardous environments.

- Integrated Performance

Systems are compatible across platforms, allowing centralized monitoring and streamlined compliance tracking. - Hazardous Area Solutions

ATEX- and OSHA-certified equipment ensures safe operation in environments with volatile materials or gases. - One Vendor. Full Coverage.

Whether you’re managing bulk material handling, on-site weighing, or mobile inventory, LSI delivers continuity and support across all weighing applications.

Ready to scale your operation with confidence? Call (559) 446-1022 or continue reading to learn why LSI is trusted by industry leaders nationwide.

Get in Touch

Reach out to our experts today and take advantage of our reliable Weighing services. Call now at (559)446-1022 or fill out the contact form below.

Family-Owned Accuracy: Your Drum Weighing Partner

When it comes to handling volatile materials or safeguarding production accuracy, experience matters. For over 50 years, LSI has delivered precision-engineered cylinder and drum scales trusted by industries across the West Coast and beyond. What sets us apart isn’t just our ±0.1% accuracy or advanced calibration—it’s our commitment to craftsmanship, service, and complete in-house control.

Every scale is proudly Made in the USA, built without subcontractors, and supported by technicians who understand your industry’s regulations and workflow. Whether you’re in logistics, chemical processing, or medical gas handling, our team tailors solutions that meet performance specs and safety codes with zero compromises.

📞 Call (559) 446-1022

📩 Email us at lsiscales@lsiscales.com

📱 Find us on Facebook and Instagram

📝 Or reach out through our contact us form to schedule your free site survey.

Let’s weigh the right way—together.

(855) 440-1022

Give us a call in Arizona :

(559)446-1022

Give us a call in Fresno: